About us

We are a leading provider of

RFID labels for various applications and challenges. With our many years of experience and extensive expertise, we develop and implement customised solutions for our customers. Our portfolio includes a wide range of RFID labels that are suitable for a wide variety of applications. Whether in

logistics,

retail or industry - our

RFID labels always offer you the optimum solution.

What are RFID labels?

RFID labels (Radio-Frequency Identification) are electronic labels that are used for wireless identification, localisation and tracking of objects in various application areas. They consist of a small microchip, which stores relevant data, and an antenna, which is responsible for communicating with an RFID reader. Both components are integrated into an RFID label that can be applied to different materials such as paper, plastic or film. This technology enables fast, contactless recording and processing of information, which optimises processes in logistics, retail, production and many other industries.

Application areas

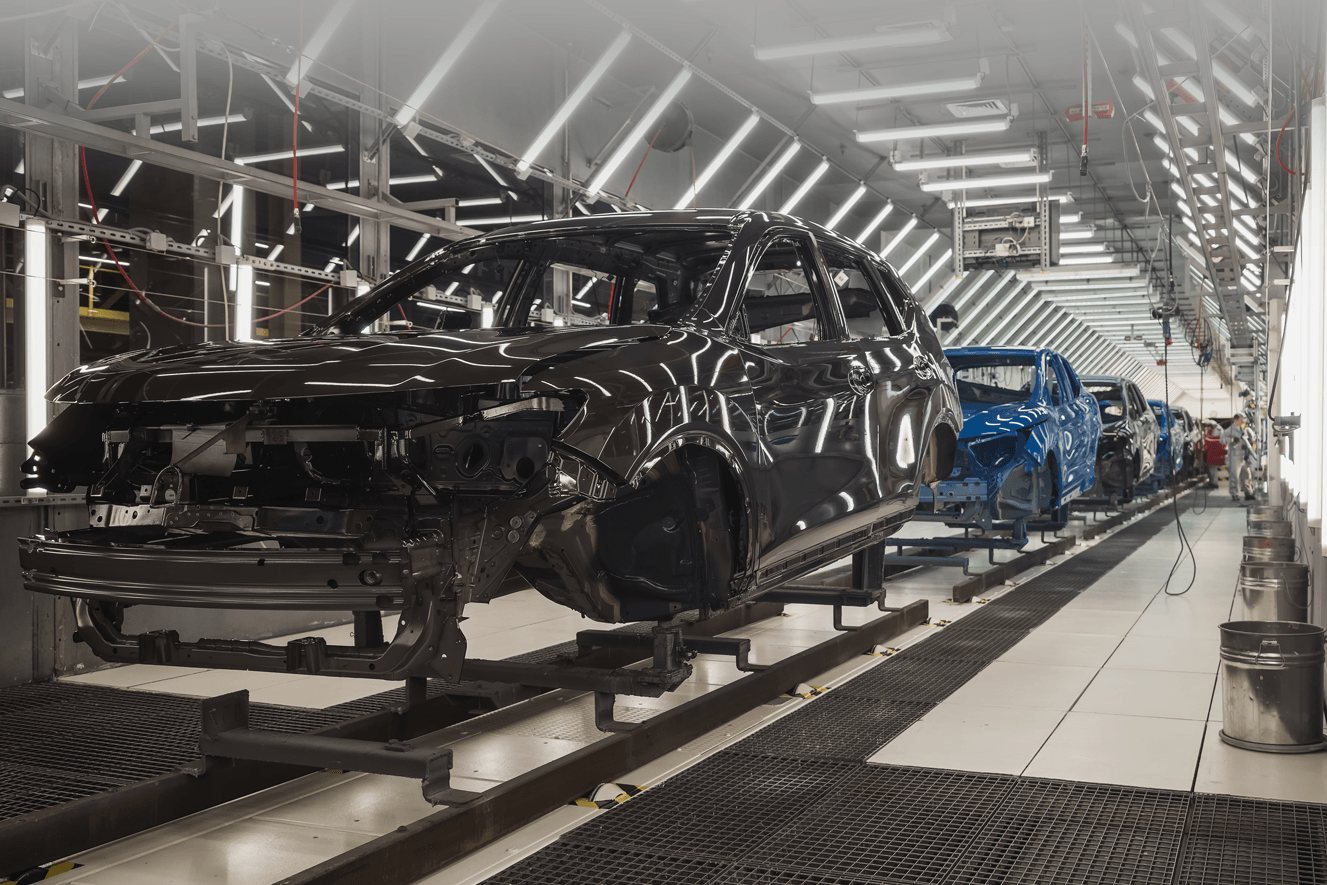

RFID systems play a central role in modern

logistics and

retail. They enable a wide range of applications: from the optimisation of production processes and efficient goods and inventory management to advanced vehicle identification. Another important area of application is the fight against product piracy. In addition, consumers regularly encounter

RFID technologies in the form of contactless payment systems. The use of RFID transponders is also widespread in the recording of working hours and in electronic locking systems. Integrated into ID cards and passports, RFID chips make a decisive contribution to the secure identification of individuals.

RFID labels also enable the efficient labelling and identification of various objects and products, which is particularly important in warehousing and laboratory analyses.

Material composition of RFID-labels

Depending on the application, our RFID labels can be fully customised in terms of label properties, RFID chip and RFID antenna. The RFID inlays, consisting of chip and antenna, are thin, flexible and can be easily integrated into various labels.

Outer material

Adhesive

RFID inlay

In which sizes do we offer RFID labels?

Our

RFID labels

are available in various standard sizes as well as customised and order-related in almost any desired label format.

What materials are RFID labels made of?

The selection of

RFID label

face materials ranges from thermo-printable or thermo-coated paper to various types of film (PE, PP, PET).

What role does the adhesive play in RFID labels?

The choice of adhesive is crucial for the application of RFID labels. We offer special adhesives that are, for example, temperature-resistant, suitable for food applications, chemical-resistant or easily removable. We will work with you to find the optimum adhesive for your area of application.

What should you look out for with RFID chips?

Both the RFID chip and the antenna can be customised to your requirements. Particular attention must be paid to the memory size of the chip and its specific reading properties. The reading range is also significantly influenced by the size and shape of the antenna.

Customised product delivery

All our RFID labels can either be supplied pre-printed or customised.

Your advantages with RFID-labels

Unlike conventional barcode labeling, RFID labels are rewritable and no visual contact is required for radio contact. Thus, it is no longer necessary to establish direct contact between the transmitter and receiver. Depending on the type of RFID transponder, reading ranges of a few centimeters to 20 meters can be achieved. In addition, the radio can easily penetrate many types of materials. Because the shape and size of the transponder can be adapted to all conditions, the RFID chip can even be integrated into the packaging or completely into the respective product. In addition, the microchip is resistant to environmental influences and the information and data can still be read without any problems even if it is extremely dirty.

Numerous advantages with RFID for logistics industry

The identification of the goods takes place within a few seconds and about 20 times faster than by means of barcode.

In this way, workflows can be simplified, accelerated and thus costs can be saved considerably, as well as the efficiency and profitability of a company can be increased many times over.

No visual contact or direct

contact necessary

Insensitivity to contamination

Identification of goods within the shortest possible time

Simplified accelerated processes lead to cost savings

Your challenges without RFID

Manual processes and untraceable inventory

lead to high costs

No individual identification or localization of goods

Lack of transparency regarding the condition and history of components and materials

solutions from Plöckl Media Group

As a specialist supplier of high-quality RFID-labels, we develop, produce and test labels for every field of application. You are provided with an extensive, continually expanded portfolio of RFID-labels for every application!

Why RFID-labels from PMG?

Development

We employ our great professional expertise to develop your customized product solution to entirely meet your requirements.

Production

During production we leave nothing to chance. We rely on the most modern machinery and to guarantee the utmost precision in each individual label.

Quality

We place importance on the use of highly modern camera monitoring systems for our quality control and thus guarantee the highest level of quality through our 100 % final inspection.

Reliability

You can always rely on the extensive know-how and advisory skills of our staff. We accompany you at all times with expertise and flexibility, from the first point of contact right through to the final execution of your project and beyond.

Quality

and

reliability

RFID labels from PMG stand for the highest quality and reliability. Strict quality controls and the use of high-quality materials ensure that our labels fulfil your requirements even under demanding conditions. Our labels are robust and resistant to heat, cold and moisture and are ideal for use in industry, retail and logistics. We work with you to develop RFID solutions that are precisely tailored to your requirements.

Green RFID Logistics

Sustainability through RFID

A poor CO2 balance is largely to blame for globalization, increased consumption and the worldwide transport of goods. Sustainable logistics is therefore one of the most important aspects of the transport and logistics industry.

Area-wide identification of goods by means of RFID tagging ensures environmentally friendly and resource-efficient logistics by accelerating, automating and optimizing logistics processes. The beauty is that the increased efficiency of smart logistics processes also makes most operations more economical. That means you save money, too. At the same time, you reduce the harmful impact on the environment. And in the end, everyone feels better about contributing to environmental protection.